GlobalMAC is the authorized service provider of SAMPSISTEMI for all its machines in the Philippines.

GlobalMAC offers the following maintenance and automation services:

1. EMERGENCY TROUBLESHOOTING/REPAIR AND PLC PROGRAM BACKUP SERVICES

We could render on-call emergency troubleshooting/repair services at your company premises on cases where you need extra manpower or your Maintenance crew will not be able to handle the problem for some reason. We can also do Siemens Step 5 and Step7 PLC program backup services if you have no available programmer. We also render after sales services for machines/equipment supplied by companies we represent.

2. INSTALLATION AND COMMISSIONING

Installation and commissioning of new or second hand machines would surely require additional manpower. If you use your Maintenance staff to do the installation, this would affect your workload and Maintenance Department’s performance would suffer. We could offer to do this job for you. This is one of our expertise as all of us from GlobalMAC have a long experience in installation and commissioning.

3. UPGRADING OF CONTROL SYSTEM

4. MACHINE MODIFICATION TO IMPROVE PERFORMANCE OR ACCOMMODATE NEW PRODUCTION REQUIREMENT.

1. EMERGENCY TROUBLESHOOTING/REPAIR AND PLC PROGRAM BACKUP SERVICES

We could render on-call emergency troubleshooting/repair services at your company premises on cases where you need extra manpower or your Maintenance crew will not be able to handle the problem for some reason. We can also do Siemens Step 5 and Step7 PLC program backup services if you have no available programmer. We also render after sales services for machines/equipment supplied by companies we represent.

2. INSTALLATION AND COMMISSIONING

Installation and commissioning of new or second hand machines would surely require additional manpower. If you use your Maintenance staff to do the installation, this would affect your workload and Maintenance Department’s performance would suffer. We could offer to do this job for you. This is one of our expertise as all of us from GlobalMAC have a long experience in installation and commissioning.

3. UPGRADING OF CONTROL SYSTEM

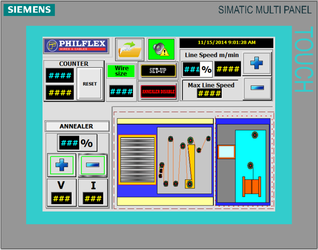

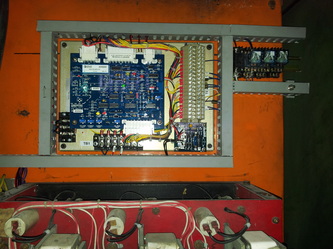

- UPGRADE OF PLC, DRIVES AND HMI. Old Siemens S5 PLC’s are already obsolete and replacement parts are hard to find and expensive. These S5 PLC’s are no longer reliable because of old age; these units can fail anytime and can cause you long downtime. Even for troubleshooting alone, you will find only few people nowadays who have the S5 programmer. We could offer to replace the whole PLC hardware package with the appropriate latest S7 PLC package and convert our S5 application software to S7. With an inclusion of HMI to the upgrade package, we can also eliminate/replace the selector switches, potentiometers, analogue meters and text display for a more lean control panel. With the new HMI we could include the Recipe function wherein you could save your production parameters for each cable type into individual recipe which can then be recalled when running again the same cable type.

- UPGRADING OF OLD AC AND DC DRIVES TO NEW SSD-PARKER DIGITAL DRIVES. Old AC or DC drives are analogue and also obsolete with hard to find and expensive spare parts. In fact, bigger percentage of downtime is caused by these old drives. Furthermore, its speed and torque regulation is inferior compared to the new digital drives. We could offer to replace all your obsolete analogue drives with the new SSD-Parker digital drives to include Profibus-ready features.

- REPLACEMENT OF THE WHOLE CONTROL PANEL. Upgrading from S5 to S7 or replacing only the analogue drives would not guarantee high machine utilization due to other factors especially the analogue boards used for synchronization and other functions. These synchronization boards are special boards that can only be purchased from machine manufacturers. The price of these boards becomes higher as these become obsolete and no longer available. Replacing these boards are very tedious work as it requires skills, knowledge and more time to tune before the machine can be brought back to operation. The ultimate solution to obsolete hardware and software is to replace the whole control panel with the latest standard control panel consisting of S7 Siemens PLC, SSD-Parker drives and Proface or Siemens HMI interlinked via Profibus and MPI. With the new set-up, the analogue synchronizing boards are also eliminated thereby making the maintenance of the system simpler and with the new hardware; your machine utilization would surely be maintained high.

4. MACHINE MODIFICATION TO IMPROVE PERFORMANCE OR ACCOMMODATE NEW PRODUCTION REQUIREMENT.

- New machines have new designs that improve the performance of the old machines. We can propose possible modification/improvements which can improve the productivity of the machine. Some examples are: better tension control, wire break detection, automated loading system, line speed synchronization, replacing DC motor with AC motor for simpler maintenance and higher PF, and many more.

- In some cases, customer needs to modify or convert the machine to accommodate new production requirement for maximum machine utilization. This may need modification of machine part or supply of additional part which entails modification in the controls and PLC program. We can make a study and submit a proposal on how to implement this modification.

System Integration

GlobalMAC is a competent system integrator using SSD-Parker Inverters and DC drives, Siemens S7 PLC’s, Mitsubishi PLC's, Siemens HMI, Proface HMI, temperature controllers and servomotors/controllers. We are also competent in programming Siemens Step 7, WinCC, TIA Portal, GP-Pro EX, MELSOFT GX. .