Liwei Double Twsit Cabling machine control upgrade

Old control:

Existing sequential and speed synchronization control was done with 2 sets Siemens S7-200, one on the main panel and the other inside the cradle communicating through Wifi. The S7-200 is still functioning well but following were the problems reported:

Control upgrade:

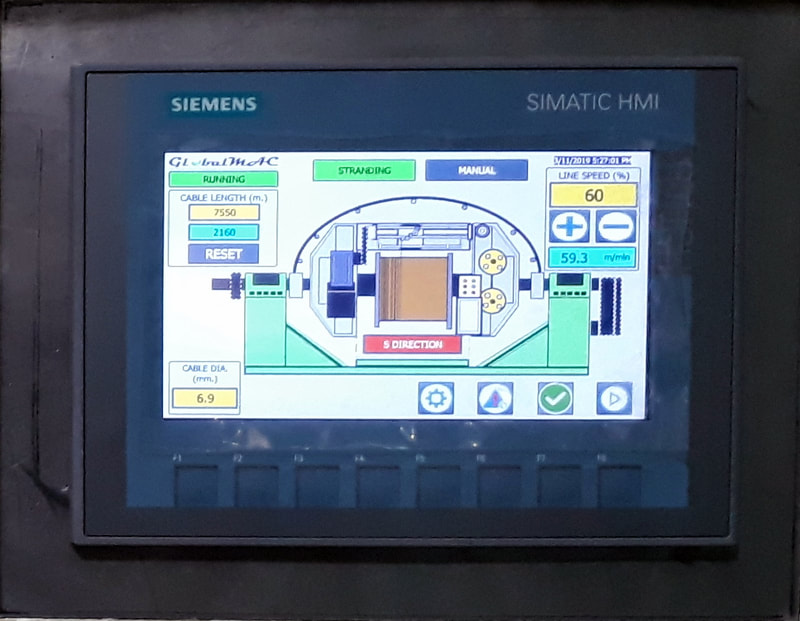

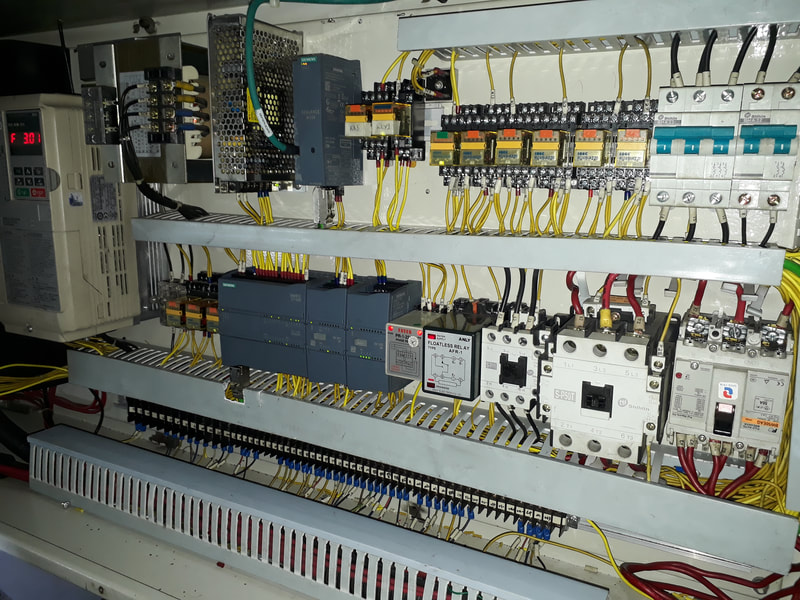

Since the PLC and HMI programs cannot be accessed for checking the problems, we replaced the whole PLC and HMI set-up with 2 sets of the latest Siemens S7-1200 PLC communicating through IWLAN and colored touch screen HMI. All the drives were retained. We made a new program using the latest Siemens TIA Portal v14 programming software adhering to the European standard employing common ramp generator for all components.

We also have to do fine tuning of the inverters minimum and maximum frequencies for correct synchronization and accurate lay/pitch.

Existing sequential and speed synchronization control was done with 2 sets Siemens S7-200, one on the main panel and the other inside the cradle communicating through Wifi. The S7-200 is still functioning well but following were the problems reported:

- Unsynchronized starting and stopping. During stopping, the reel continues to rotate while the capstan and the bow already stopped causing straight lay on the lay plate. As the machine starts, the loose lay makes overlapping as the cable is being twisted inside the cradle.

- Lay was not accurate.

- The traverse can only be set to one pitch (lay) regardless of the size of the cable being produced.

- The PLC and HMI programs cannot be accessed because both are password protected and the supplier do not disclose the password.

Control upgrade:

Since the PLC and HMI programs cannot be accessed for checking the problems, we replaced the whole PLC and HMI set-up with 2 sets of the latest Siemens S7-1200 PLC communicating through IWLAN and colored touch screen HMI. All the drives were retained. We made a new program using the latest Siemens TIA Portal v14 programming software adhering to the European standard employing common ramp generator for all components.

We also have to do fine tuning of the inverters minimum and maximum frequencies for correct synchronization and accurate lay/pitch.