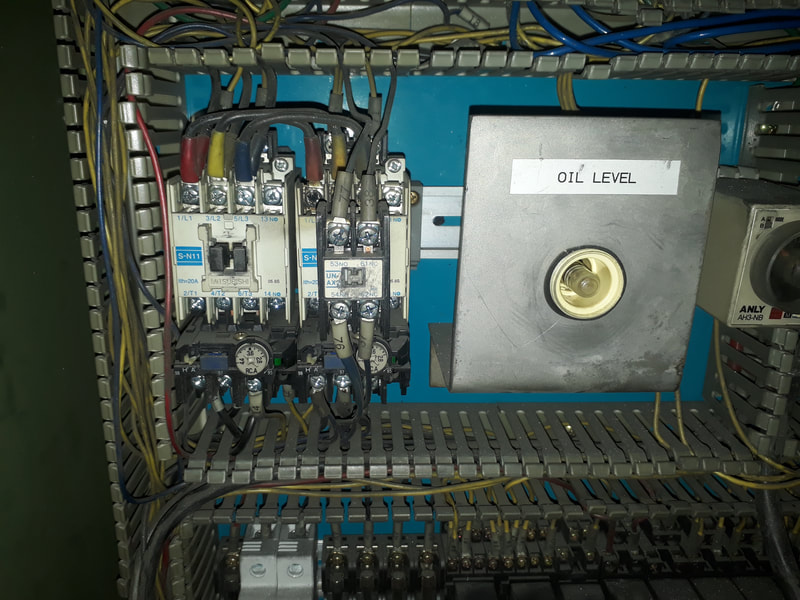

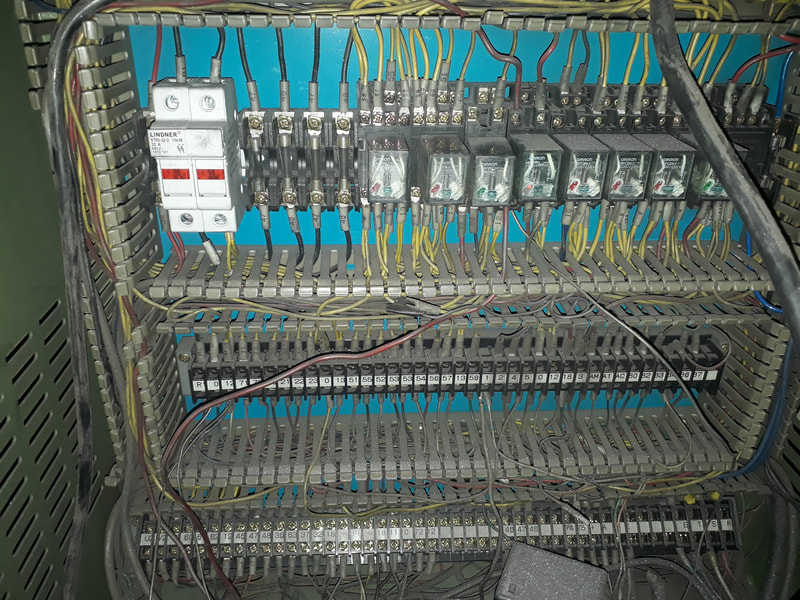

SANFENG 1000MM BUNCHER CONTROL UPGRADE

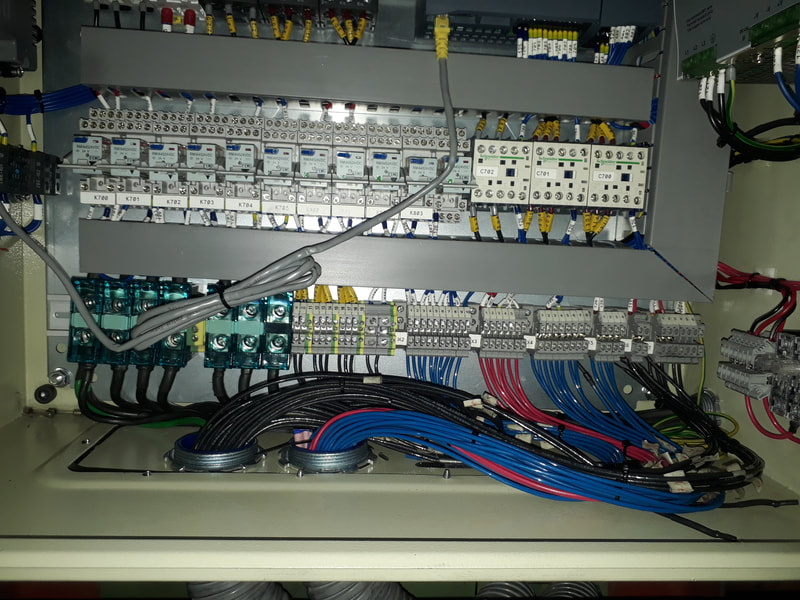

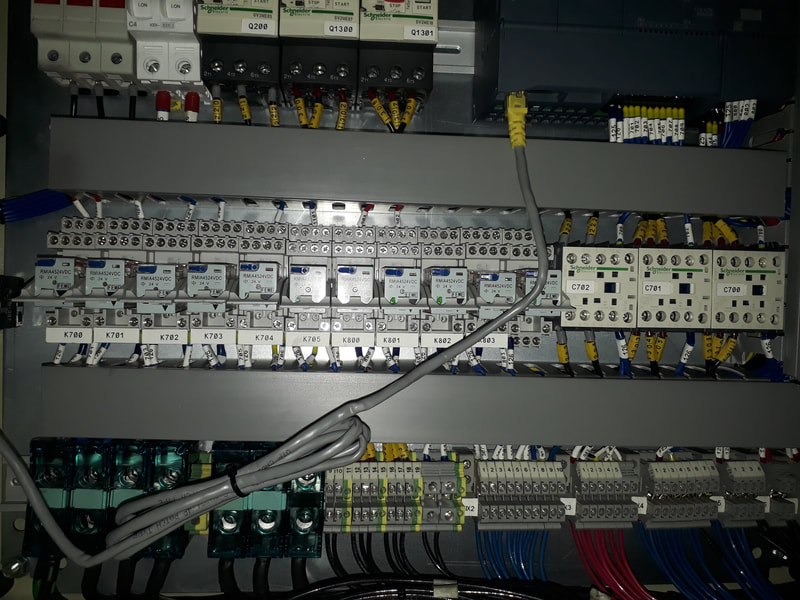

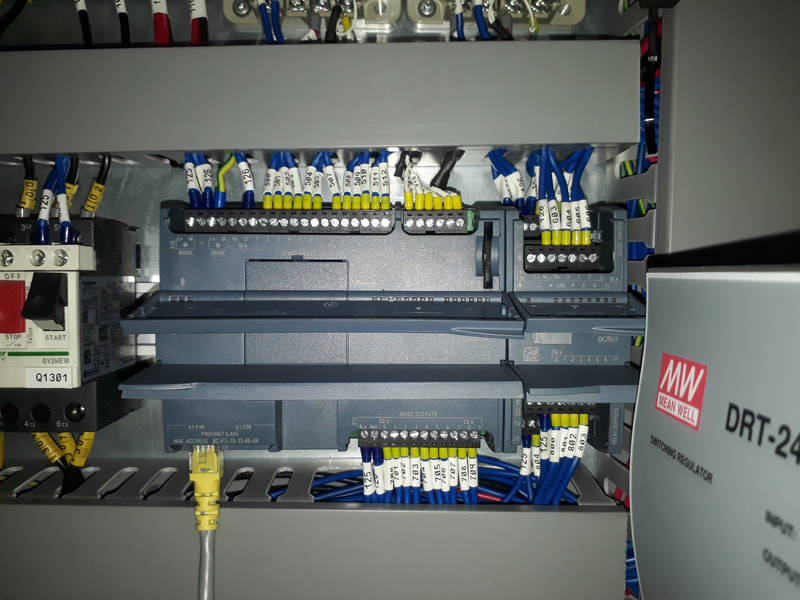

The original control was purely hardwiring consisting of relays for sequence interlocking. We supplied a new control cabinet with Siemens S7-1200 PLC , 7" touch-screen Simatic KTP700, Parker AC10 inverter, Euntay 24VDC tension controller and all other necessary control components. With the new control system, following features are now enjoyed by the production:

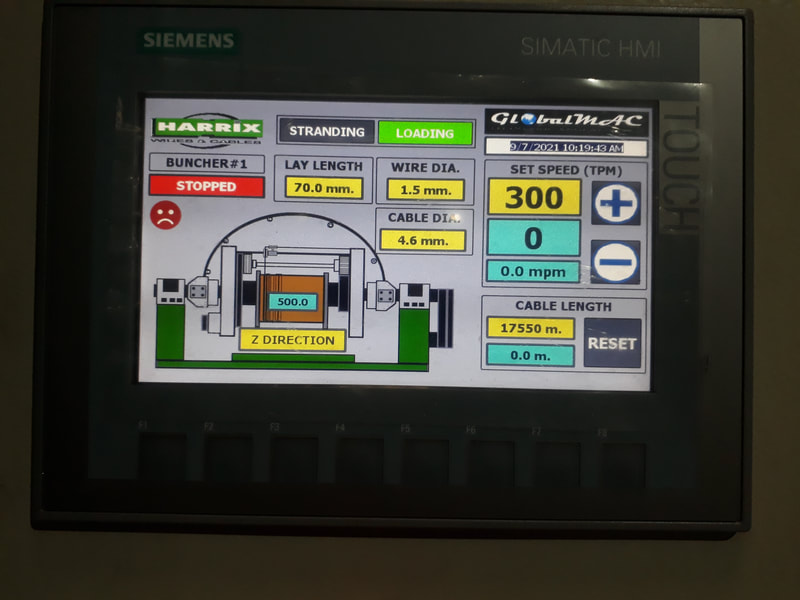

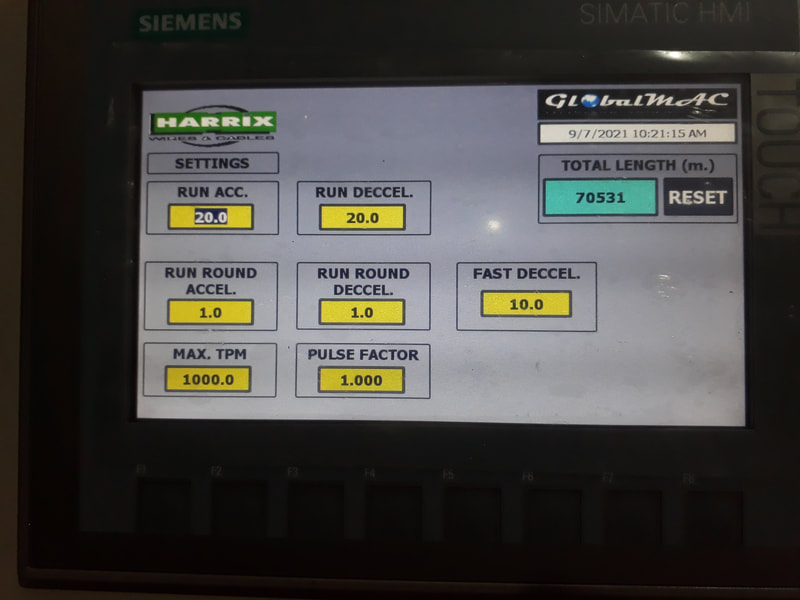

- All production set-up parameters are now set in the HMI. No more potentiometers for setting speed and tension thus the settings are more precise. Actual speeds are also displayed.

- Alarms are now displayed in the HMI thus the Operator will know immediately what is the existing fault and therefore can immediately resolved the problem. We have also the alarm history for checking the faults that occurred for the last number of days for evaluation of reoccurring problems.

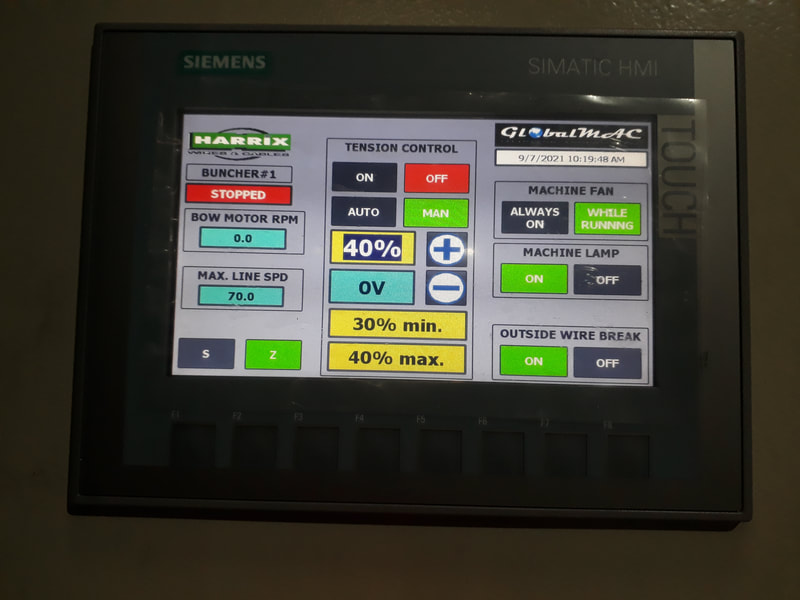

- Tension control now has two options, Auto and Manual.

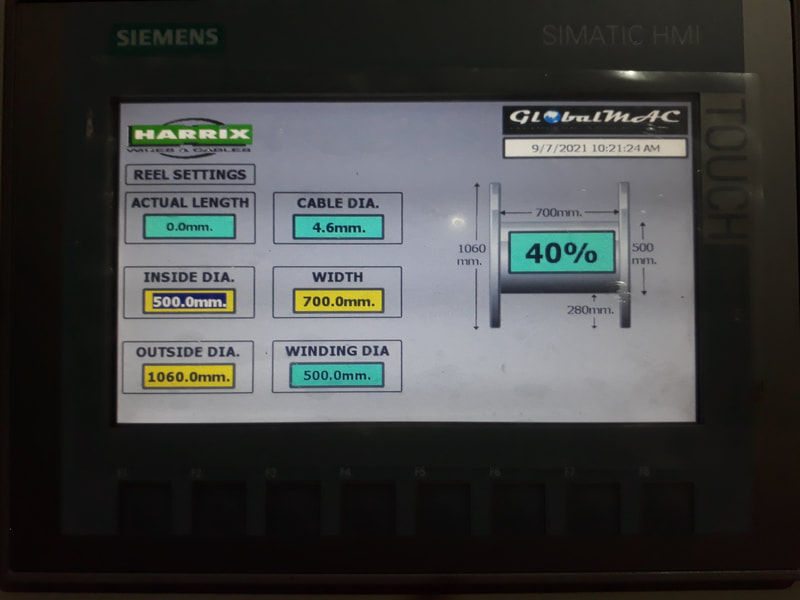

- For Manual mode, the Operator manually sets the tension in the HMI to its desired value and adjust it accordingly as the winding diameter increases by length.

- For Automatic mode, the Operator inputs only the initial tension during the start of the production. The tension will automatically increase according to the actual winding diameter. Even it is automatic, the operator can still adjust the tension accordingly if he thinks it is not enough or too tight.